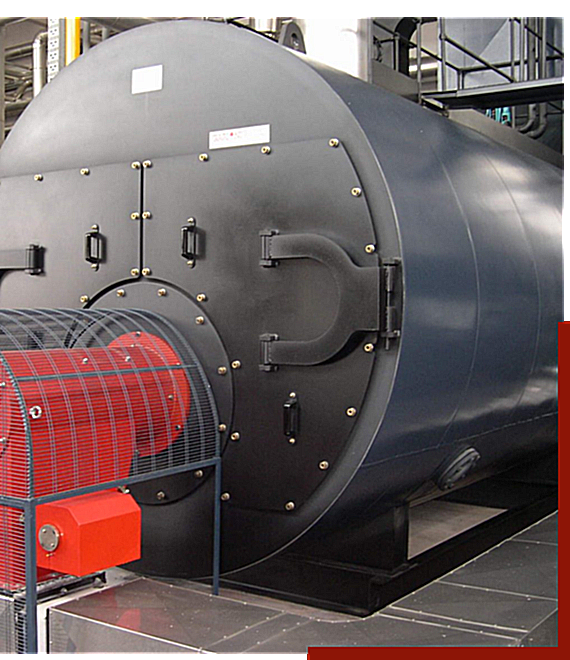

Oil and Gas Steam Boiler

Modèle WNS2-1.25-Y/Q(LN30)

The WNS2-1.25-Y/Q model is a high-efficiency industrial boiler designed for applications requiring increased evaporation capacity. It delivers optimal performance with a low carbon footprint and high reliability.

| Parameter | Detail |

|---|---|

| Nominal working pressure | 1,25 MPa |

| Evaporation capacity | 2 tonne per hour |

| Nominal steam temperature | 193°C |

| Supported fuels | Natural gas / Light oil |

| Combustion efficiency | Gas: 99.2% / Oil: 98.7% |

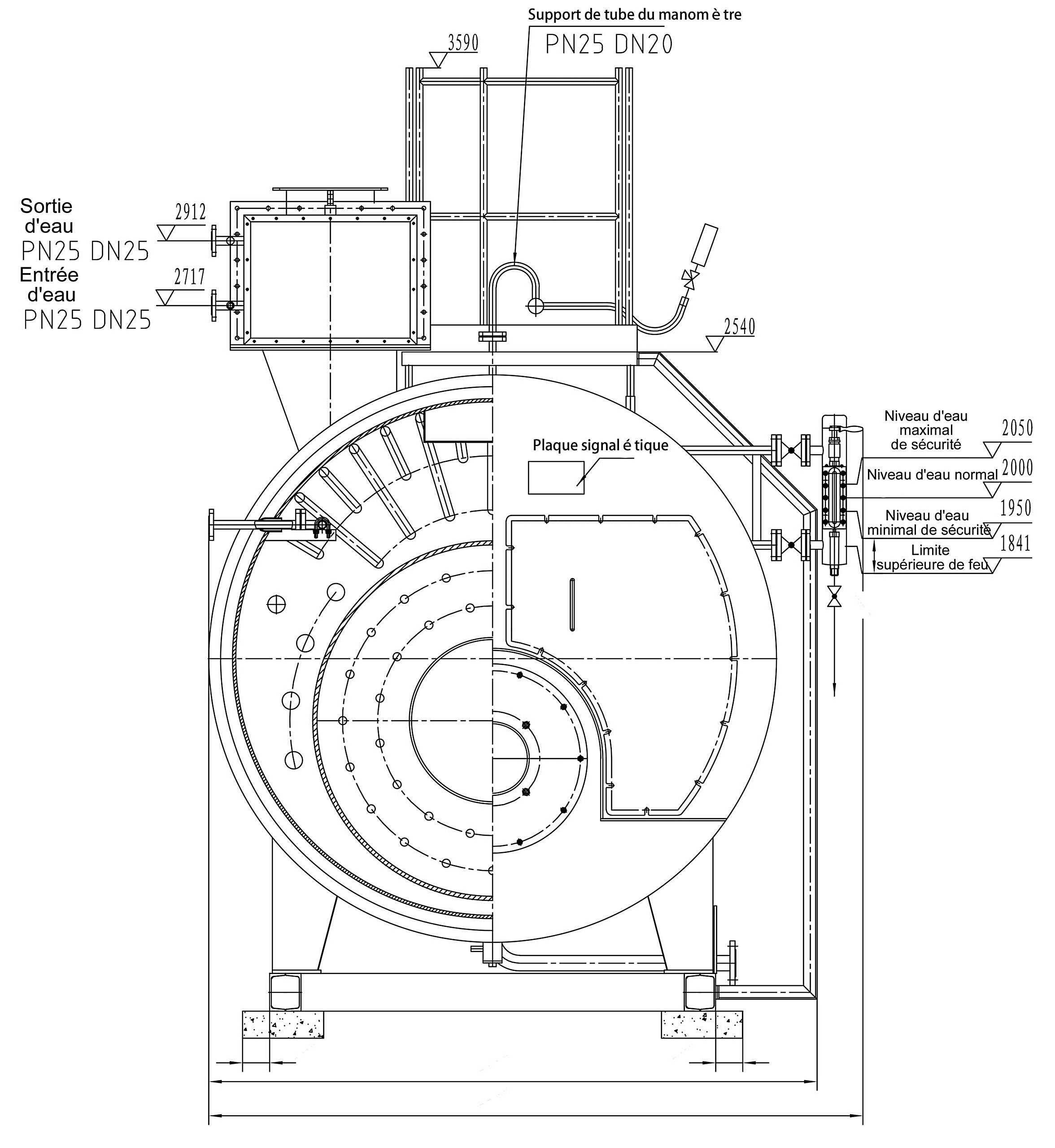

| Average water volume level | 6,3 m³ |

| Volume d'eau moyen | 4,56 m x 2,72 m x 3,90 m |

| Weight | 8,27 tonnes |

| Emission projects | Particles | SO2 (mg/m3) | NOX (mg/m3) |

|---|---|---|---|

| Gas (mg/m3) | <20.0 | <50 | <30 |

| Fuel oil (mg/m³) | <20.0 | <100 | <185 |

- Nominal steam flow rate 2t/h

- Nominal steam pressure 1.25MPa

- Nominal steam temperature 193°C

- Make-up water temperature 20°C

- Fuel oil combustion gas temperature 57.8°C

- Flue gas temperature of the gas: 57.5°C

- Design efficiency of fuel oil 98.5%

- Design efficiency of gas: 98.07%

- Gas consumption: 125.3kg/h

- Gas consumption 141.2NM3/h

- Operating weight of the boiler 13.4t

- Radiation heating surface 11.1M²

- Convection heating surface 24.4M²

- Economizer heating surface: 16.075M²

- Heating surface of the condenser: 19.29M²

- Condenser outlet temperature 46.3°C

- Condenser circuit flow rate 2t/h

- Weight of the boiler equipment 7.2t

- Useful water volume of the boiler 6.2M3

- Design fuel: Natural gas, light fuel oil

- Lower heating value of light fuel oil 42.9MJ/Kg

- Lower heating value of natural gas 38.27MJ/Nm3

- The height of the chimney must not be less than 8 meters

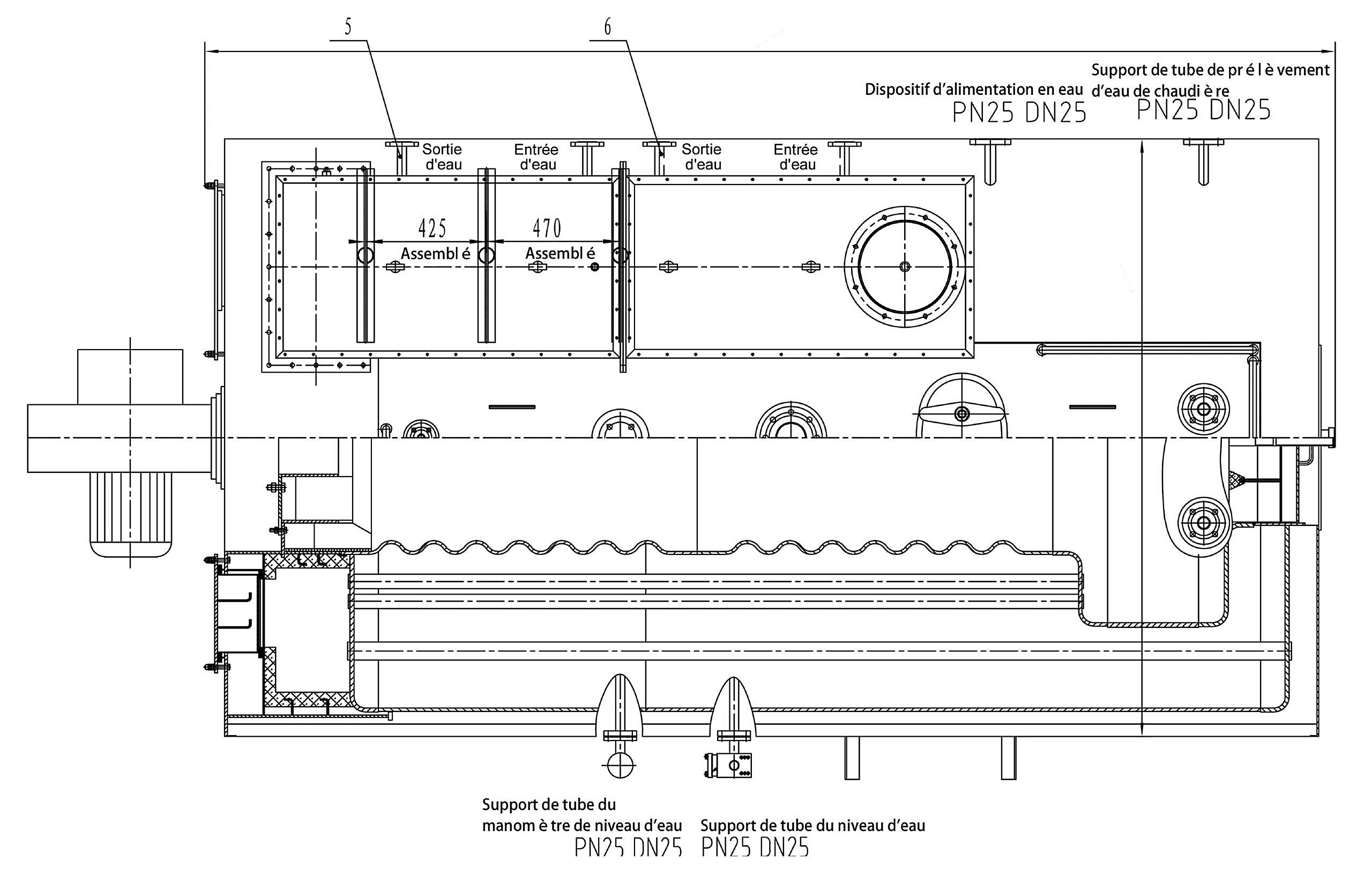

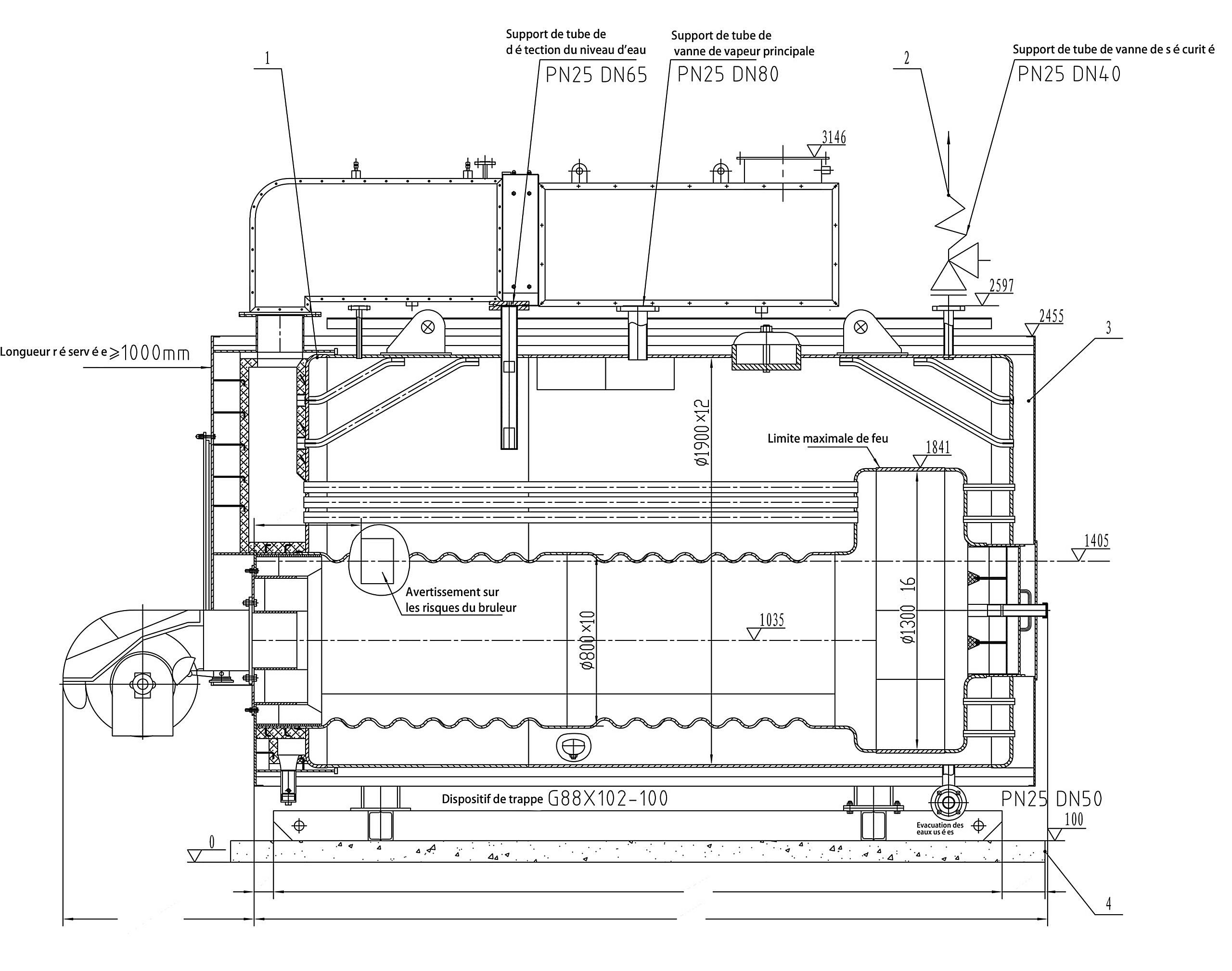

- Maximum dimensions of the boiler (length x width x height) 4565*2420*3490

- Maximum dimensions of the transportable parts of the boiler (length x width x height) 3972*2250*2517

| Num | Drawing number | Name | Qua. | Materials | Weight |

|---|---|---|---|---|---|

| 1 | HGY21008-1-0 | Main body | 1 | Component | 4615.4 |

| 2 | HGY21008-2-0 | Piping, Instruments, and Valves | 1 | Component | |

| 3 | HGY21008-3-0 | Emballage | 1 | Component | 2116 |

| 4 | HGY21008-4-0 | Fondation | 1 | Component | |

| 5 | HGY21008-5-0 | économiseur | 1 | Component | 277 |

| 6 | HGY21008-6-0 | Condenser | 1 | Component | 244 |

| 7 | HGY21008-7-0 | Steam distribution cylinder 273 | 1 | Component | 111.8 |

Technical requirements

The design, manufacture, inspection, installation, and use of the boiler must comply with the following standards:

- The design, manufacturing, and inspection of the boiler must comply with the TSG 11-2020 standards (Boiler Safety Technical Regulations), NB/T 47034-2021 (Technical Conditions for Industrial Boilers), and GB/T 16508-2013 (Shell Boilers), and must meet the requirements of TSG91-2021 (Construction Standards and Acceptance of Boilers for Energy and Environmental Protection).

- The materials of the pressure parts of the boiler must be selected in accordance with the requirements of TSG 11-2020.

- The installation of the boiler must comply with the GB50273-2022 standards (Construction and Acceptance Standards for Boiler Installation Work).

- After final assembly, a hydraulic pressure test must be performed in accordance with GB/T 16508.4-2013 (Shell Boilers - Part 4: Manufacture, Inspection, and Acceptance). The test pressure is 1.77 MPa, with a pressure hold time of 20 minutes.

- The painting and packaging of the boiler must comply with the NB/T47055-2017 standards (General Technical Conditions for Coating and Packaging of Boilers).

- The boiler burner must be selected and supplied by the company. If the user needs to select a burner under special circumstances, they must confirm that the selected burner meets the company's requirements regarding burner configurations and parameters. The burner selection and its requirements are detailed in the installation and operation manual, and the burner adjustment must follow the instructions on the 'warning panel' of the burner. The quality of the boiler water must comply with the GB/T1576-2018 standards (Standards for Atmospheric Pollutant Emissions from Boilers).

- The condenser must not be used under pressure, and the chimney connections must not bear any weight. The steam cylinder diagram is not included; it is reserved for use in the boiler room.

- The design of this boiler takes into account the latent heat of vaporization released during condensation.

| Working pressure | Working temperature | Design volume |

|---|---|---|

| =<1.25MPa | Saturated steam | 0.06m3 |

| Design temperature | Test pressure | Working medium |

|---|---|---|

| 193°c | 1.875MPa | Water vapor |

| Burner | Model | Electrical power |

|---|---|---|

| light fuel oil | RLS190/M MZ | 5.9 kw |

| Natural gas | RS200/E FGR | 5.5 kw |

| Water supply pump | Circulation pump |

|---|---|

| CDL4-16 Q=3m3/h H=140m 3kW | SGL32-125 Q=6.5m3/h H=18m 0.75kw |

| Total electrical power of the boiler: approximately 12 kW (including the burner, the feedwater pump, the electrical control panel, and the circulation pump) |